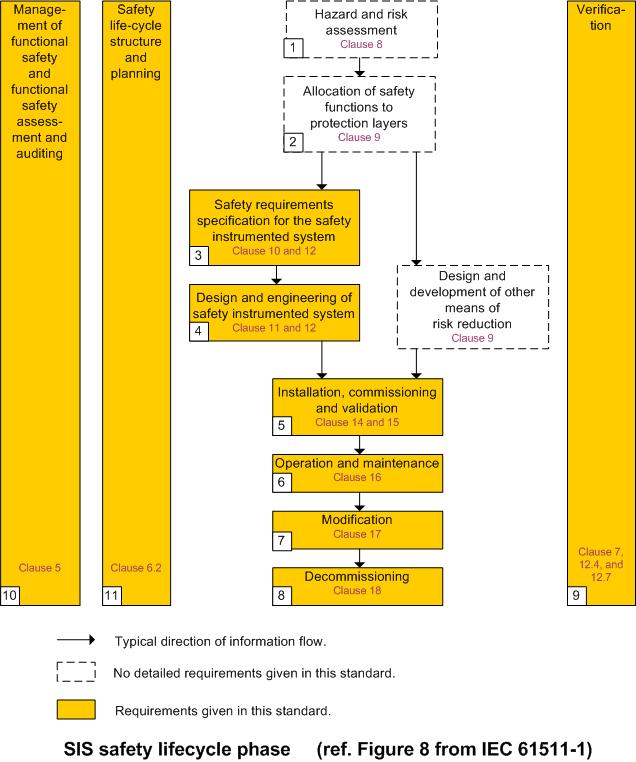

SSL considers functional safety to be a core activity of its business. The following table lists our experience and strengths across the functional safety life-cycle (IEC61511).

IEC61511 Lifecycle Phase | SSL Profile | Clients |

Hazard ID | Hundreds of reviews facilitated across several sectors. See table 2 for more detail. Training and qualification of leaders and participants across NZ. | All MHF & Petroleum Clients 20+ years experience |

SIL Determination & Risk Assessment | Hundreds of scenarios assessed to determine SIL levels using LOPA and Risk Graph techniques. Several SIL assessment procedures developed. LOPA & SIL training conducted across NZ and Australia. | All MHF & Petroleum Clients 20+ years experience |

SIS Requirements Specification (SRS) | Development of several company standards and specification of numerous safety functions. SSL have three TUV certified Functional Safety Engineers. | Ballance Agri-nutrients Todd Energy Vector Contact Energy Evonik Top Energy |

Design | Use of SIL Solver/ ExSILEntia to design and verify the design in accordance with the SRS | Balance Babbage Consultants Origin Evonik STOS Todd Energy Vector Contact Energy Worley Waste Petroleum Combustion Top Energy |

Operation and Maintenance | Operational procedures (bypass, proof testing) to satisfy compliance with standards. | Ballance Agri-nutrients Vector Pan Pac |

Modifications | Design of MoC systems for plant and software changes | MoC audits of many companies Westside NZ Ltd Pan Pac TOP Energy Ngati Tuwharetoa |

Functional Safety Management Plan | Developed several functional safety management systems and audited many companies against the IEC standard. | Balance Vector Westside Pan Pac Greymouth Petroleum City Rail Link (Victoria) |

Functional Safety Assessments/ Audits | From Functional Safety Assessment of individual SIL functions through to full Functional Safety Management System Audits | Refining NZ Pan Pac Evonik Contact Ngati Tuwharetoa |